Hot Selling for Pipe Sandblasting Equipment - Mechanical Recycling Sand Blasting Booth – DX-BLAST

Hot Selling for Pipe Sandblasting Equipment - Mechanical Recycling Sand Blasting Booth – DX-BLAST Detail:

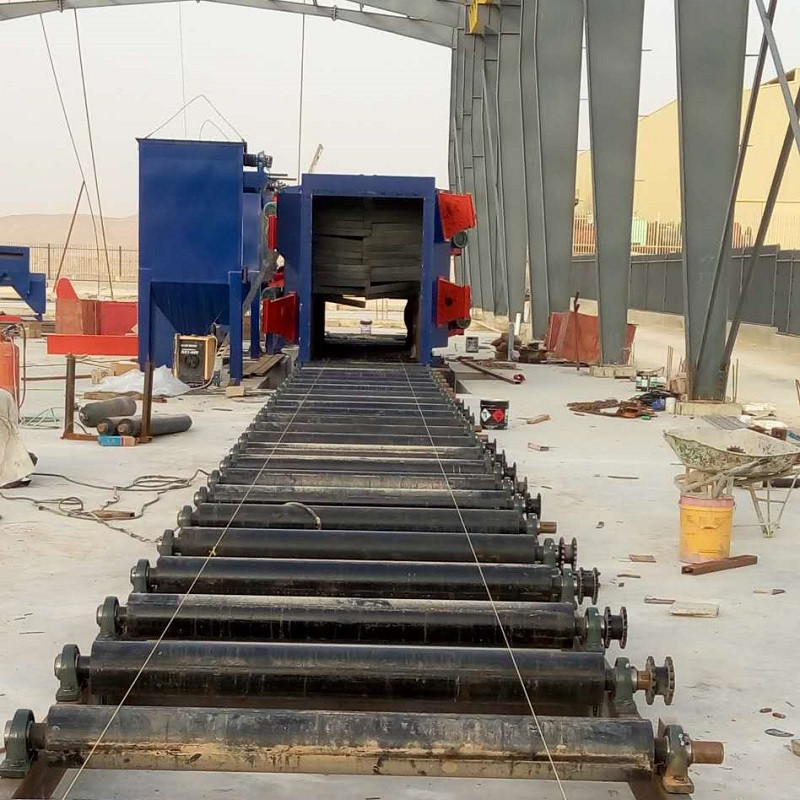

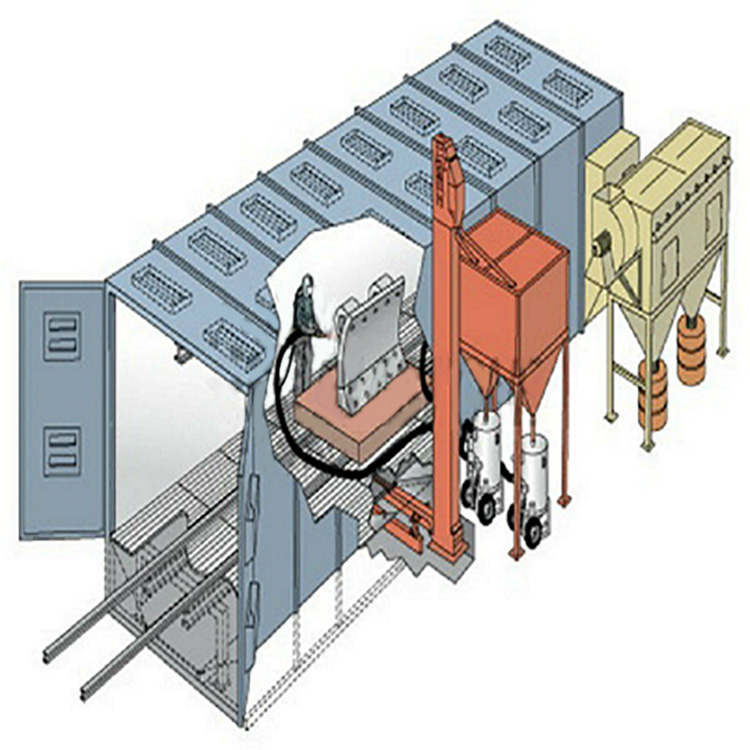

Manual sand blasting booth mainly includes Blasting chamber, Sandblasting tank, Abrasive circulation system, Lighting system, Dust Collector, trolley system, Electric control system and other parts. The surface finish level can achieve Sa2.5.

Blasting body is made of sandwich panel and steel plate, it is a strong, seal and spacious operation space to clean the workpiece. Blasting chamber is consist of body shell, left and right side wall, lateral wall, roof, protection plate, etc.

| Technology parameter: | ||

| Part I : Processed work pieces and parameter | ||

| 1 | The sand blasting chamber internal size (L*W*H) | 8000*6000*5000 mm |

| 2 | The sand blasting chamber door size(W*H) | 6000*4000 mm |

| 3 | Max.workpiece weight | Max.workpiece weight |

| 4 | Finish levelCan achieve | Sa2 .5 (GB8923-88) |

| 5 | Processing speed | 15-30 m2/hour (A-D level original surface material and workpiece cleaning requirements, operator start different blasting guns quantity) |

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.

Product detail pictures:

Related Product Guide:

Devon Windsor delivers devilish look in plunging red top at the Chiara Boni show during NYFW | Sand Blasting Booth

2020 BMW 330i and M340i: Everything you want to know about the new 3-Series | Tumble Belt Cast Parts Shot Blasting Machine

With this motto in mind, we've got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for Hot Selling for Pipe Sandblasting Equipment - Mechanical Recycling Sand Blasting Booth – DX-BLAST, The product will supply to all over the world, such as: France, Hanover, Cape Town, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.