The performance and variety of shot blasting equipment have great development. The foundation is a large number of experimental studies on the main components and fragile parts of shot blasting equipment. All kinds of shot blasting machine cleaning equipment are carefully designed and developed. Casting production on the shot blasting equipment, the main requirements are: clean up the internal and external of the castings rapidly & make parts have the long life, so it can be said that experimental research and design of shot blasting equipment, basically around these two requirements and carried out.

Stone blasting machine is Suitable for small scale, occasional surface cleaning or reinforcement treatment in fabrication, construction, chemistry, electric machinery etc. particularly for variety casting, forging, zinc alloy casting and steel structure surface cleaning and surface strengthening, to scan small amount of viscous sand and oxide skin on workpiece surface. Also suitable for surface cleaning and strengthening of heat-treated pieces, especially for difficult collision of long and thin, thin wall parts cleaning. Shot blasting machine adopts direct motor drive, frequency conversion motor.

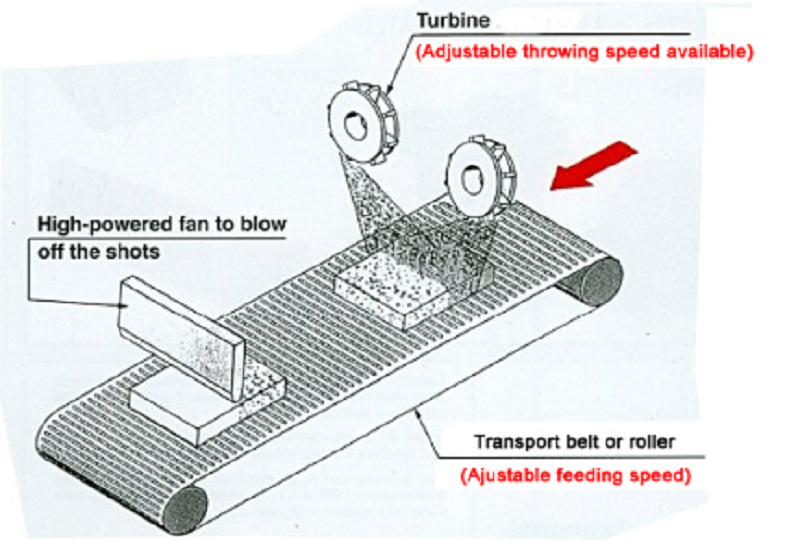

Stone shot blasting machine,marble surface cleaning Shot blasting machine work principle: shot blasting machine for continuous feeding of high-function continuous operation to clean up, deal with large quantities, energy saving, sturdy and durable, beautiful appearance is the biggest feature of the machine. In the process of cleaning the electrical control of the frequency conversion motor drive roller will be sent to the workpiece cleaning room in the body of the projectile area, the whole body by four different coordinates from the strong strength of the projectile and the impact of friction, so that the workpiece oxidation Skin and its dirt quickly fall off, the workpiece surface to get a certain roughness of the smooth surface. Fall into the workpiece above the projectile and rust through the recovery of the spiral conveyor to the projectile circulation system, by the outer side of the workpiece loading and unloading.

Stone processing technology is growing today, the shot blasting rough surface processing technology will undoubtedly fill the rough surface of the stone processing, for the stone application provides another new attempt, and for the architect provide a new aspect of the stone finishes. Over time, company’s quality and reputation as the basis for many domestic and foreign customers with high-quality products and the best service.

Post time: Jan-07-2019