For the surface cleaning of various steel, steel profile, structural parts, the most widely used is the shot blasting machine and peening machine. In recent years, shot blasting machine is gradually replacing the peening machine in the market, some experts even asserted: a few decades later, peening machine will disappear.

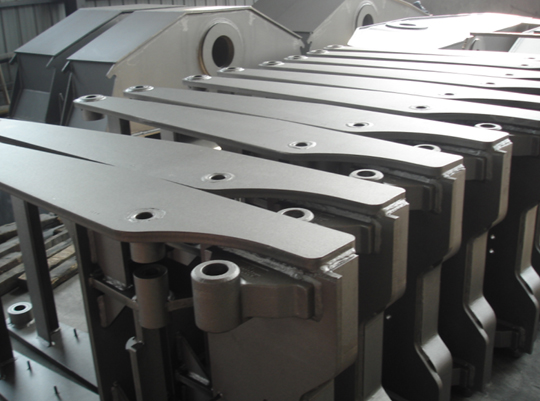

First of all, the peening machine is a cleaning machinery to use of high-speed compressed air will sand (pills) directly hit the surface of the work piece, so that the surface of the work piece to change; and shot blasting machine is a cleaning equipment to use blasting device to blasting the surface of work piece. The pros of shot blasting machine is that shot blasting machine is to reduce the fatigue life of the parts to increase the surface stress, increasing the strength of the parts to achieve the purpose of strengthening the work piece.

Second, the application of peening machine is more extensive, it has a better effect in cleaning up all the impurities on the metal surface, such as oxide, rust and old paint, the rust quality, rust efficiency is as high as 4-5m2 / H, but because the abrasive is not recyclable, so clean up the scene becomes trouble, but also caused serious pollution; and shot blasting machine in the metal surface impurities, also increase the metal internal dislocation density, improve the metal surface strength. Its rust quality is very good, rust efficiency is also very high. And it is high production efficiency, low cost, high degree of automation, can be achieved pipeline operation, less pollution to the environment.

Environmental protection and energy conservation is the biggest issue in the 21st century, obviously, shot blasting machine will replace peening machine.

Post time: Jan-07-2019