Europe style for Plate Blasting - Automatic Air Blasting System with Belt Conveyor – DX-BLAST

Europe style for Plate Blasting - Automatic Air Blasting System with Belt Conveyor – DX-BLAST Detail:

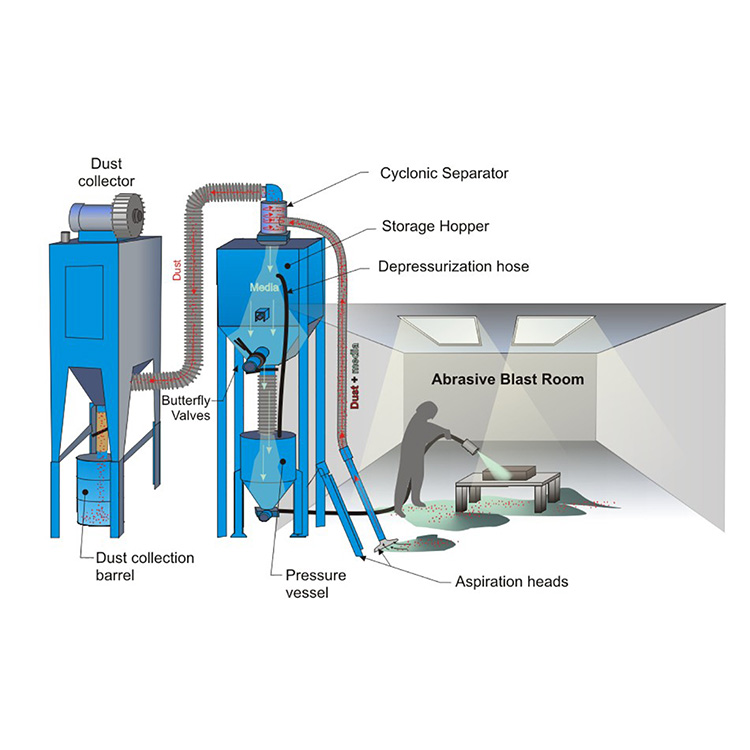

Robotic Air Blasting System with Belt Conveyor: the operator is inside the room during the blasting process. A protective suit and a helmet protect the operator from abrasive impact, and a fresh air supply provides sufficient ventilation through the blaster’s helmet.

Below size of blasting room is for customers’ reference. When you have different requirements, please let us know the size of blasting jobs, size of blasting room and quantity of spray guns, we can design blasting room according to your requirements.

Technology parameter:

| Robotic Air Blasting System with Belt Conveyor | ||||

| No. | Model | Size of room | Size of jobs | Spray gun quantity |

| 1 | DX-0606-M1 | 6000×6000×5000mm | 3000×3000×2500mm | 2 |

| 2 | DX-0606-M2 | 6000×6000×6000mm | 3000×3000×3500mm | 2 |

| 3 | DX-0806-M1 | 8000×6000×5000mm | 5000×3000×2500mm | 2 |

| 4 | DX-0806-M2 | 8000×6000×6000mm | 5000×3000×3500mm | 2 |

| 5 | DX-1006-M2 | 10000×6000×6000mm | 7000×3000×3500mm | 2 |

| 6 | DX-1506-M2 | 15000×6000×6000mm | 12000×3000×3500mm | 2 |

| 7 | DX-1508-M2 | 15000×8000×6000mm | 12000×5000×3500mm | 2 |

| 8 | DX-1808-M2 | 18000×8000×6000mm | 15000×5000×3500mm | 4 |

| 9 | DX-0806-M3 | 18000×10000×8000mm | 15000×7000×5500mm | 4 |

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

| Packing & Delivery: | ||

| 1 | Package | Standard package |

| 2 | Delivery time | 50 days after receiving the down payment |

| 4 | Quality Warranty | One Year |

| 5 | After-sales Service Provided | Engineers available to service machinery overseas |

FAQ:

1). Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2). Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3). Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4). Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

5). Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. We have never got any complaint from our customers.

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.

Product detail pictures:

Related Product Guide:

The Lexus ES 300h is a chill luxury sedan Engadget Engadget save share Close save share save share save share save share save share ear icon eye icon text file vr | Road Surface Shot Blasting Machine

WWE Star Dean Ambrose Poised to Return to ‘Raw’ Tonight After Injury | Tumble Belt Cast Parts Shot Blasting Machine

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for Europe style for Plate Blasting - Automatic Air Blasting System with Belt Conveyor – DX-BLAST, The product will supply to all over the world, such as: Kenya, Pakistan, New Delhi, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.