Factory Supply Automatic Grinding Machine Tools L140 L170 Diamond Resin Bond And Metal Bond Granite Diamond Fickert Abrasive For Granite

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Factory Supply Automatic Grinding Machine Tools L140 L170 Diamond Resin Bond And Metal Bond Granite Diamond Fickert Abrasive For Granite, For more information, please send email to us. We are looking forwards the opportunity to service you.

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Diamond Fickert Abrasive, Fickert Abrasive, Granite Diamond Fickert Abrasive, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our solutions. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed.

cast stainless steel shot is widely used for the surface preparation by peening and blasting on Copper, Aluminum, Zinc and stainless steel work pieces etc.. Thus the work can illustrate their metal color with sub-light effects and die casting restlessness after preparation. There is no need to adopting rust moving treatment by acid cleaning. Besides their abrasion resistance is 3-5 times as much than cast stainless steel shot, so the production could be cut down.

Size: 0.2mm-3.0mm.

Hardness: 200-450/400-600/600-700HV.

Density: 7.7g/cm3 Min.

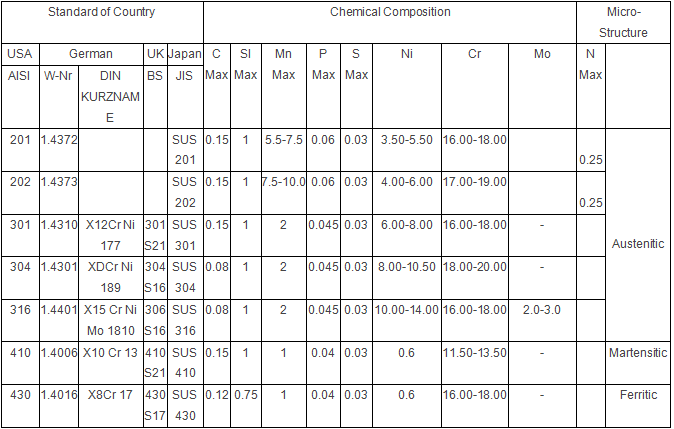

Available Grades: SUS 304, SUS 202, SUS 430.

Long life time/longer durability.

Specification:

PS: Our company can according to customer’s special requirements, provide other chemical composition of the stainless steel shot.

Feature:

1: Stainless cut wire shot has a significantly longer useful life than cast steel shot or grit and carbon cut wire shot

2: Dust generation is significantly lower so blasting operations are much cleaner

3: Stainless cut wire produces excellent results because of its uniformity and strength

4: It will make you a “Greener” organization because disposal of spent media will be significantly reduced (You won’t need as much shot, inventory requirements will be lower and in-bound freight less)

5: You will NOT introduce ferrous contamination to non ferrous castings or work objects as occurs with the use of cast steel or carbon cut wire shot

Apply to equipment:

Stainless Steel Shots are typically used for the blasting machine with drum type, chain type, lifting hook type, crawler type, pass type, rotating table type, accumulation type, marching type and car type. Also can used for shot blast equipments, pretreatment of the production line, and sand blasting room.

Packaging & Delivery:

Packaging Details:

1) 25kg per bag, 40 bags in one pallet

2) Generally, one 20GP container can load 25 tons, 27 tons at most.

3) We can also pack the products as you requirements.

4) Store in a dry place. No safety risk but oxidation and aggregation may occur in the presence of moisture. Handle with care to avoid damage to packaging to avoid spillage.

5) Lifetime: it is 2500-2800 times in the normal condition.

6) Our package is moisture-proof bag.

Delivery Detail:

7 days after payment

FAQ:

Q1: How long does it take on average to develop a sample?

A: Generally, samples will be finished within 1-3 working days.

Q2: What is the production time?

A: Production time are different from different products, the production time is 15-20 days after sample approval and receiving your deposit.

Q3: What is the payment terms?

A: Normally, we accept 30% deposit and the balance by B/L copy.

Of course it is negotiated for some special orders, we can also accept L/C at sight.

Q4: What is the minimum qty ?

A: 1000KGS or 5 tons according to different products.

Q5: Can I visit your factory ?

A: We warmly welcome customers visit us. Before you come here, please kindly tell me your schedule, we can arrange specialized salesman to guide you.

Q6: Can we use our own shipping agent?

A: Yes, you can. We had cooperated with many forwarders. If you need, we can recommend some forwarders to you and you can compare the price and services.