Factory making Environmental Sand Abrasive Blasting Room - Cast Steel Shot – DX-BLAST

Factory making Environmental Sand Abrasive Blasting Room - Cast Steel Shot – DX-BLAST Detail:

Steel Shotused for sandblasting steel structure:

Chemical composition: C:0.80-1.2%, Si:≥0.4%, Mn:0.60-1.2%, S:≤0.05%, P:≤0.05%.

Density: >7.3g/cm.

Hardness (±3HRC): HRC40-50, HRC50-60,HRC60-65.

Specification:

![V}@OKSJAE[{IVME26W%P]]5](/uploads/d9adf27e.png)

Application:

1) auto and manual blasting of metal products (casting, forging, steel constructions, pipelines)

2) shot peening of heavy-loaded parts (shafts, carriage springs, springs, cog-wheels)

3) ragging(pinch-pass rolling) of rolls in rolling mills

4) as a filling of casting molds in foundry

5) as a reinforcing constituent of composite materials

6) metal surface cleaning before painting

7) descaling of steam-boilers

8) surface treatment of stone, granite, marble and natural stone-cutting

9) cleaning of cutting tools

10) surface preparation of parts for galvanic coatings, enameling

11) surface preparation of oil and gas pipeline for multi-layer coatings

12) cleaning of oil-storages and reservoirs

Packaging & Delivery:

Packaging Details:

1) 25kg/pp(paper) bag, 40 bags in one ton bag.

2) 25 kg/pp(paper)bag, then 40 bags on one pallet

Generally, one 20GP can load 25 tons, 27 tons at most.

All packages are lined with waterproof materials.

We can also pack the products as you requirements.

Delivery Detail:

In 7 days after advanced payment.

1) Store in a dry place. No safety risk but oxidation and aggregation may occur in the presence of moisture. Handle with care to avoid damage to packaging to avoid spillage.

2) Lifetime: it is 2500-2800 times in the normal condition.

3) Our package is moisture-proof bag.

FAQ:

1) Q: What is the mode of your payment?

A: T/T: 30% In advance payment and the rest 70% against B/L copy.

L/C:100% irrevocable L/C at sight.

2) Q: What’s the MOQ of your product?

A: MOQ is 5 tons.

3) Q: Can you provide the free samples?

A: Yes, we can send free samples with freight collect. By express, such as DHL,TNT, Fedex, Aramex, etc.

4) Q: What standards you carring out for your products?

A: SAE standard and ISO9001, SGS.

5) Q: Customized Service:

A: Product—We can produce various sizes abrasive according to the customers’ requirements.

Package—The products can be packaged as customers’ requirments.

6) Q: After-sale Service:

A: Our products passed ISO9001 standard, and we control the testing procedure strictly. From the raw materials to the transport to port, our staffs do their works seriously and responsibly all the time. If there are quantity problems, package problems, delivery problems, or any other problems, our company will seriously investigate the event and give customers a satisfying reply.

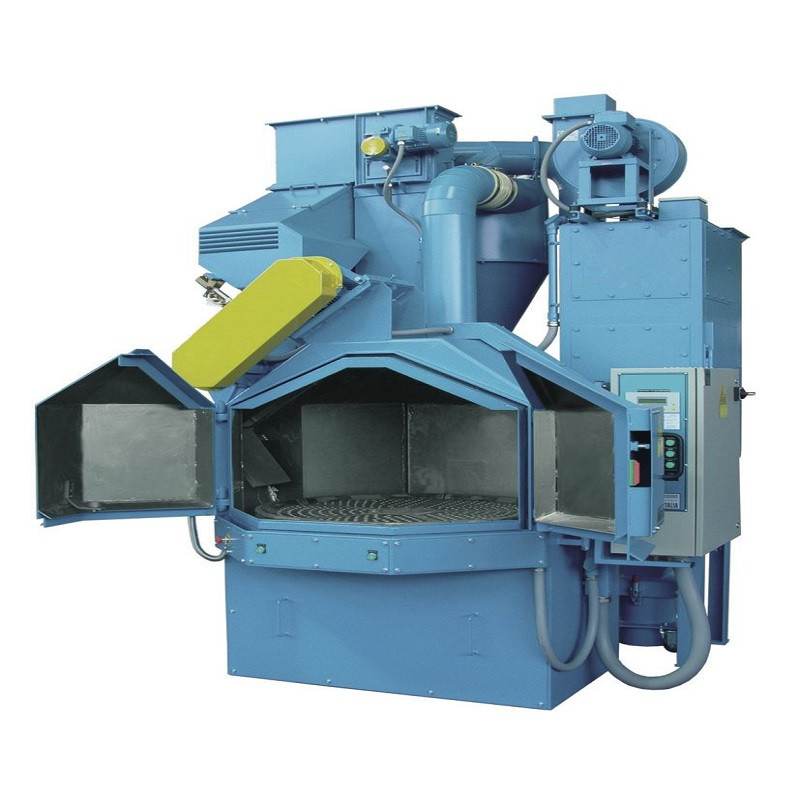

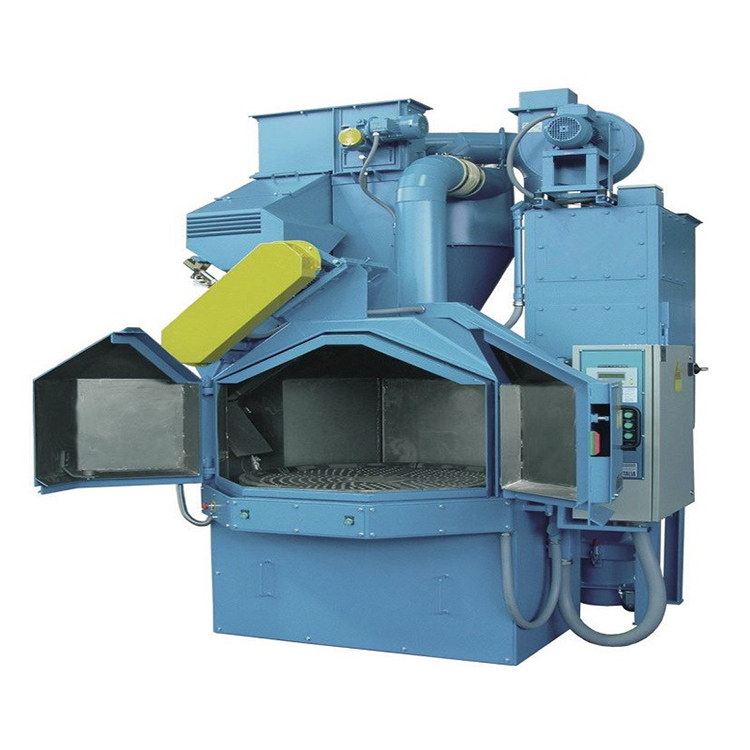

Product detail pictures:

Related Product Guide:

The Big and Definitive List of PS4 Couch Multiplayer Games – Every Known Game Listed | Sand Blasting Booth

USS San Diego: Scientists search WWI shipwreck to solve military mystery | External Steel Pipe Shot Blasting Machine

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of Factory making Environmental Sand Abrasive Blasting Room - Cast Steel Shot – DX-BLAST, The product will supply to all over the world, such as: Boston, kazakhstan, Bangkok, Our mission is "Provide Products with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.