China Supplier Turntable Shot Blast Cleaning Manchine - Steel Pipe Outer Wall Shot Blasting Machine – DX-BLAST

China Supplier Turntable Shot Blast Cleaning Manchine - Steel Pipe Outer Wall Shot Blasting Machine – DX-BLAST Detail:

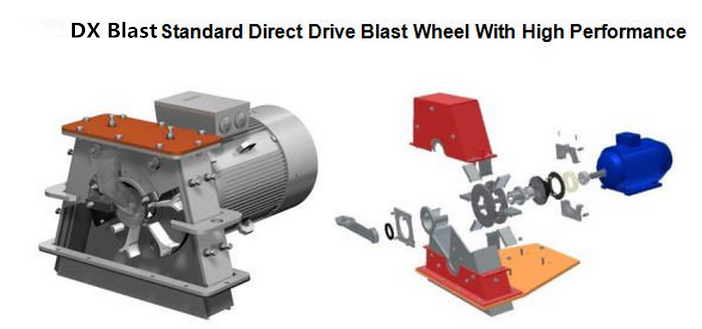

Features:

1. Compact design, simple operating principle.

2. Excellent blast performance.

3. Great service life.

4. Tough, hard wearing, manganese clast cabinet.

Applications:

1. Structural Steel.

2. Mill Scale Removal.

3. Profiling.

4. Paint Preparation.

These Type of Machines consist of under mentioned Parts:

1. Main Blast Cabinet with inspection Door.

2. Blast Wheel Units with Drive Mechanism.

3. Abrasive circulation unit.

4. Bucket Elevator unit.

5. Abrasive Separation/Cleaning system with Storage Hopper.

6. Dust Collector with Cleaning Mechanism.

7. Roller Conveyor system at Inlet & Outlet Side.

8. Control Panel with Siemens Brand PLC Control System

Technical Parameters:

Size of Chamber

1. width : 1400mm

height : 1400mm

2. The Roller Conveying System

working speed : 1.0-5m/min

reducer power : 3kw

distance with each roller: 6000mm x 2

3. Blast Nozzles(6 sets)

model: Q034II

rotating speed: 8–70mm/s

max.volume for blasting: 6×250kg/min

power : 6 x 15kw

4. Quality Grade

surface quality : Sa2-Sa2.5(GB8923-88)

surface roughness : 15~50um(GB1031-83)

Equipment Noise(area) Operation ≤95dB

If you’re interested in our style machine, welcome to contact us to get more detailed info.

FAQ:

1. The max. Length/Width/Height of the work pieces.

2. The productivity you need to blasting the work pieces ( how many tons or pieces per day or per month?).

3. The power supply you need( such as 380V, 3P, 50HZ).

4. The work pieces photo or drawing is better.

Based on this question, the detailed technical proposals will be sent to you for reference.

Product detail pictures:

Related Product Guide:

Global Sandblasting Machine Market | Research Detailed Report 2019-2023 (AB SHOT TECNIC, S.L,Blasting) and more… | Rotary Table Shot Blast Equipment

Here’s What We Think We Know About Sacha Baron Cohen’s Secret New Show | Road Surface Shot Blasting Machine

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for China Supplier Turntable Shot Blast Cleaning Manchine - Steel Pipe Outer Wall Shot Blasting Machine – DX-BLAST, The product will supply to all over the world, such as: Cancun, Brasilia, Lesotho, We have our own registered brand and our company is developing rapidly owing to high quality products, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!