China OEM Q36 Turntable Shot Peening Machine - Steel Pipe Outer Wall Shot Blasting Machine – DX-BLAST

China OEM Q36 Turntable Shot Peening Machine - Steel Pipe Outer Wall Shot Blasting Machine – DX-BLAST Detail:

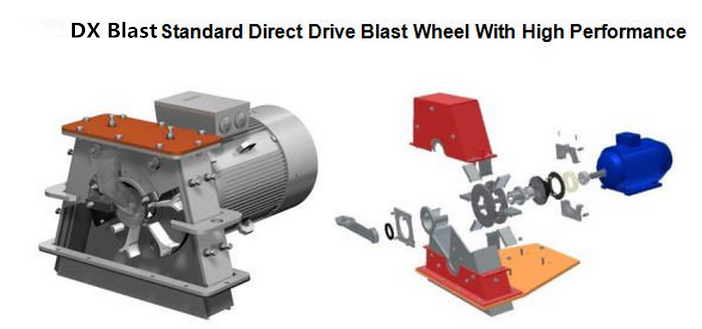

Features:

1. Compact design, simple operating principle.

2. Excellent blast performance.

3. Great service life.

4. Tough, hard wearing, manganese clast cabinet.

Applications:

1. Structural Steel.

2. Mill Scale Removal.

3. Profiling.

4. Paint Preparation.

These Type of Machines consist of under mentioned Parts:

1. Main Blast Cabinet with inspection Door.

2. Blast Wheel Units with Drive Mechanism.

3. Abrasive circulation unit.

4. Bucket Elevator unit.

5. Abrasive Separation/Cleaning system with Storage Hopper.

6. Dust Collector with Cleaning Mechanism.

7. Roller Conveyor system at Inlet & Outlet Side.

8. Control Panel with Siemens Brand PLC Control System

Technical Parameters:

Size of Chamber

1. width : 1400mm

height : 1400mm

2. The Roller Conveying System

working speed : 1.0-5m/min

reducer power : 3kw

distance with each roller: 6000mm x 2

3. Blast Nozzles(6 sets)

model: Q034II

rotating speed: 8–70mm/s

max.volume for blasting: 6×250kg/min

power : 6 x 15kw

4. Quality Grade

surface quality : Sa2-Sa2.5(GB8923-88)

surface roughness : 15~50um(GB1031-83)

Equipment Noise(area) Operation ≤95dB

If you’re interested in our style machine, welcome to contact us to get more detailed info.

FAQ:

1. The max. Length/Width/Height of the work pieces.

2. The productivity you need to blasting the work pieces ( how many tons or pieces per day or per month?).

3. The power supply you need( such as 380V, 3P, 50HZ).

4. The work pieces photo or drawing is better.

Based on this question, the detailed technical proposals will be sent to you for reference.

Product detail pictures:

Related Product Guide:

How Fox News covered Kanye West’s White House visit compared to rappers during the Obama years | Rotary Table Shot Blast Equipment

TIGER – Every Day Should Be Saturday clock menu more-arrow no yes Horizontal – White Horizontal – White Horizontal | Road Surface Shot Blasting Machine

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for China OEM Q36 Turntable Shot Peening Machine - Steel Pipe Outer Wall Shot Blasting Machine – DX-BLAST, The product will supply to all over the world, such as: Indonesia, Casablanca, Macedonia, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.