Special Design for Spare Parts - Rebar shot blasting machine – DX-BLAST

Special Design for Spare Parts - Rebar shot blasting machine – DX-BLAST Detail:

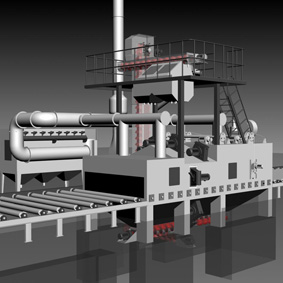

Rebar shot blasting machine consists of roller conveyor system, blasting system, abrasive circulation system (separator, bucket elevator, screw conveyor), dust collection system and electric control system. The surface finish level is Sa2.5.

Technical Parameters:

1. The machine dimensions See the drawing

2. Shot blasting chamber Width1300mm X Height 500mm

opening size

3. Max. workpiece size 12000mm X (8-40)mm

(Length X Diameter)

4. Max. workpiece weight 500kg

5. Finish level Sa2.5 (IS08501-01)

6. Surface roughness 40~85 μ (Depend on abrasive size)

7. Noise ≤95dB

8. Dust content after cleaning 10mg/m3

If you’re interested in our style machine, welcome to contact us to get more detailed info.

DX HIGH PERFORMANCE TURBINE

FAQ:

1. The max. Length/Width/Height of the work pieces.

2. The productivity you need to blasting the work pieces ( how many tons or pieces per day or per month?).

3. The power supply you need( such as 380V, 3P, 50HZ).

4. The work pieces photo or drawing is better.

Based on this question, the detailed technical proposals will be sent to you for reference.

Product detail pictures:

Related Product Guide:

Power Trip Unveil Ferocious New Song ‘Hornet’s Nest’ | Rotary Table Shot Blast Equipment

BBC – Future | External Steel Pipe Shot Blasting Machine

We'll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for Special Design for Spare Parts - Rebar shot blasting machine – DX-BLAST, The product will supply to all over the world, such as: Manila, Swansea, Plymouth, We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.